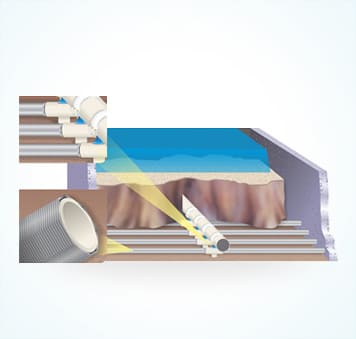

Under Drain System

Proven Technology and proven product for new and old filter plants

The Apollo Under Drain system is based on Header-lateral design. The laterals are manufactured from all welded wedge wire screens fitted with internal uPVC distributor pipes.

The unique design of the welded wedge wire screen provides uniform collection during the filtration cycle and uniform distribution during backwash is achieved with the internal PVC pipe.

The all welded wedge wire screen has small aperture and coupled with the smooth surface, allows the sand (filter media) to be directly retained without the need for a gravel layer.

Design of Apollo

Under Drain Systems

- All welded wedge wire laterals

- Air Backwash to each lateral

Comparison of Apollo Under drain system and other systems

The Apollo Under drain system is design to optimize filter bed performance, ensuring years of uninterrupted service. Due to the direct media retention possible with the Apollo Under drain system, typical problems such as mud ball formation, media loss, upset beds and non-uniform washing are all but eliminated.

Cost benefits of Apollo Under Drain System

- Removing support gravel offers higher capacity for each filter resulting in fewer beds required to achieve plant capacity.

- Fewer beds mean reduced construction costs of the plant.

- Savings in equipment requirement - e.g. pipes and valves.

- Reduced wash water volume.

- Reduced power consumption

- Lower media costs - no support gravel required

- Major down time eliminated as bed upsets are eliminated.

Features and Benefits of system

- Welded wire screen apertures as small as 0.15 mm allows direct retention of media.

- Removal of support gravel layer means reduced head loss of filter bed.

- All welded wedge wire construction provides larger open area and reduced slot entrance velocity.

- Increased open area enables higher flow rate and increased filter capacity.

- Elimination of support gravel allows increased media bed depth and more effective treatment.

- Air / water backwash is unique to each lateral, resulting in uniform backwash of the entire bed.

- More vigorous backwashing possible, resulting in cleaner bed and extended cycle times.

- Entire system is made of Stainless steel/ uPVC.

© Copyright 2016, Apollo Screens