Mining

- Dewatering

- Separation

- Classification

- Grading

- Product recovery

The all welded construction offers unmatched benefits

- Maximum open area

- Flexibility in design

- Enhanced regidity

- Increased wear life

- Higher strength

- Ease of installation

Industry

Segments

- Coal Mines

- Iron Ore Processing Plants

- Steel Mills

- Coal Processing Plants

- Mineral Processing Units

- Iron Ore Mines

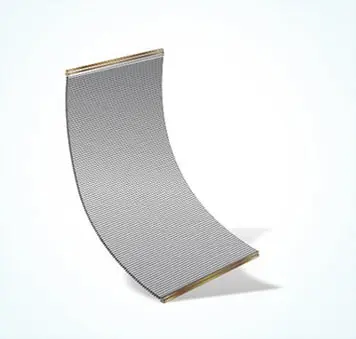

Sieve Bends

Sieve bends are custom made/ designed cross flow curved screens. The profile wire has a slight tilt (initial flow) presenting the leading edge to the feed maximizing dewatering capacity.

Sieve bends are used for sizing, dewatering or classification application in coal, Iron ore and various other mineral processing plants. Apollo screens offers sieve bends to suit sieve units of standard width or to suit customer requirement.

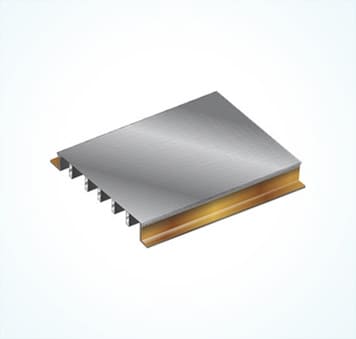

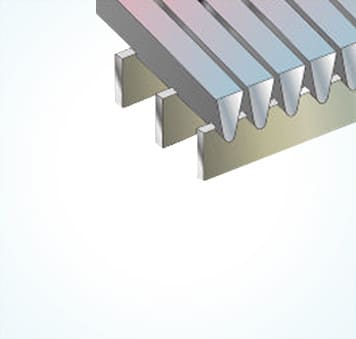

Flat Panels

The all welded flat screen panels are the optimum screen media for vibrating screens. The flat screen panels are used in sizing, dewatering and classification in Coal, Iron Ore and other mineral processing applications.

For added strength the all welded construction allows the use of strip rods or fins up to a height of 50 mm.

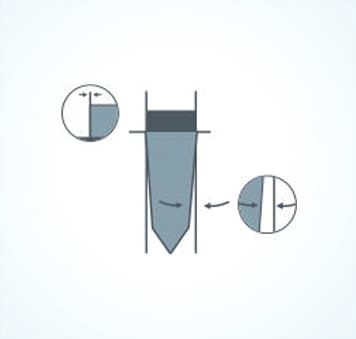

Centrifuge Baskets

Apollo Screens supplies centrifuge baskets for most coarse and fine centrifuges used in coal preparation plants. The Apollo Screens centrifuges baskets are built to exacting specification and quality standards.

All Apollo Screens baskets are supplied with wire profiles tested over decades in coal preparation plants around the world, offering optimum service life, open area and through-put. Heavy duty wires are also available to suit customer requirements.

Design & Construction Features

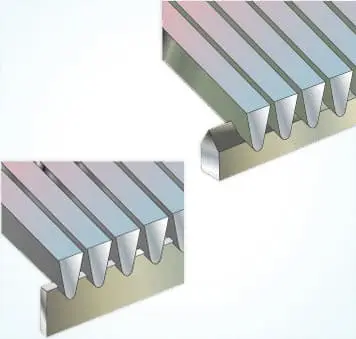

HIGHER OPEN AREA

Apollo Screens offers a wide range of wire profiles to maximize open area. Our application engineers area available to support you in selecting of the optimum wire for your application. The use of peaked support rods ensures negligible effect on open area. Maximum efficiency of your process is assured with the high open area of Apollo Screens wedge wire.

FLEXIBILITY IN DESIGN

The all welded wedge wire screens are available in various combinations of profile wires and support rods. This offers significant flexibility in designing the most suitable product for individual operations.

For enhanced strength, wedge wire products made from taller profile wires and support rods are available to suit various applications. The in-house production of wedge wire at Apollo Screens offers significant flexibility in supply of profile wires to suit specific process requirements.

LONGER LIFE

The all welded construction of the Apollo Screens products extends the service life of your wedge wire screens. Wear life can be further enhanced by increasing the size of the wedge wire and adjusting the relief angle to suit your process. Our application engineers are available to make suitable recommendations based on the needs of your process.

INCREASED STRENGTH

Each intersection of profile wires and support rods are resistance welded, resulting in a single metal. This makes the joint significant stronger than other screen media available for mineral processing e.g. looped wedge wire.

Further changes to wedge wire panel strength can be made by selecting different support rods and adjusting the span between support rods, without compromising open or significantly affecting screen panel weight

© Copyright 2016, Apollo Screens