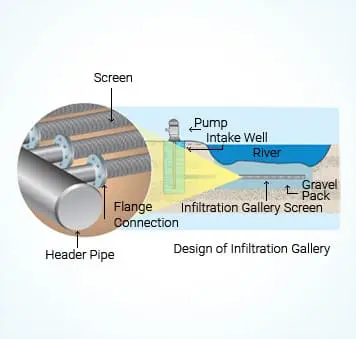

- Used to extract sub-surface water from river bed where conventional drilling may not be possible

- Screen is installed at a depth of approximately 3 metres (10 ft)

- Screen surround is covered with gravel

- Screen to screen joints are flange connections

- Each screen row is connected to main header pipe

- Water percolating through surrounding area will be collected through screen

Pack Screens

Apollo Pre-Pack Screen segment for Intake Well

- To filter suspended solids from flowing water

- Pre-Pack wedge wire screens are installed on outer wall of intake well

- Pre-Pack screens are manufactured from wedge wire screens

- All Pre-Pack screens are supplied with surround frame

- Frames are bolted together inside opening of well

Advantages

- Larger percentage open area - hence higher flow

- Available options for screen apertures - enhanced sand control

- Screen apertures inwardly opening - non clogging benefits of wedge wire

- Material of screens stainless steel 304 or 316 - minimized corrosion and extends wear life

- Available in diameters and lengths / sizes to suit site conditions.

Apollo Gravel Pack Water well screen

The application for Gravel Pack water well screens is in unconsolidated formation, where conventional gravel pack is economically unviable and normal well development is doubtful.

Apollo Pre-pack consists of an inner and outer wire wrap screen packed with smooth accurately sized natural gravel. The pre pack material is installed in the annual space between the inner and outer screen.

This design allows closer contact between screen and aquifer improving well development, efficiency and installation time - reducing overall costs.

Gravel-Pack screens have relatively high porosity, which combined with their very high permeability minimize pressure drop. To ensure selection of a correctly sized gravel pack requires sieve analysis of a sand sample from the surrounding formation.

The installation of the gravel pack between the inner and out screen takes place in the factory, prior to shipping of screens to drill site.

A number of different gravel-packs are available.

Advantages of Pre-Pack Screens

- 100% gravel packing ensured

- Eliminates conventional gravel pack

- Sand pumping eliminated

- Increased well efficiency

- Reduced drilling cost

© Copyright 2016, Apollo Screens